Email: rebekah@cdhbtech.com Tel: 86-18631261092

Email: rebekah@cdhbtech.com Tel: 86-18631261092

The baseball cap is a hat that everyone likes, and it looks very simple, but its production process is not simple. Today this article will degrade it. How is the baseball cap making?

Fabric Material. Baseball caps are generally made of cotton, cotton blends, jersey mesh, wool, acrylic/wool blends, and moisture-wicking fabrics.

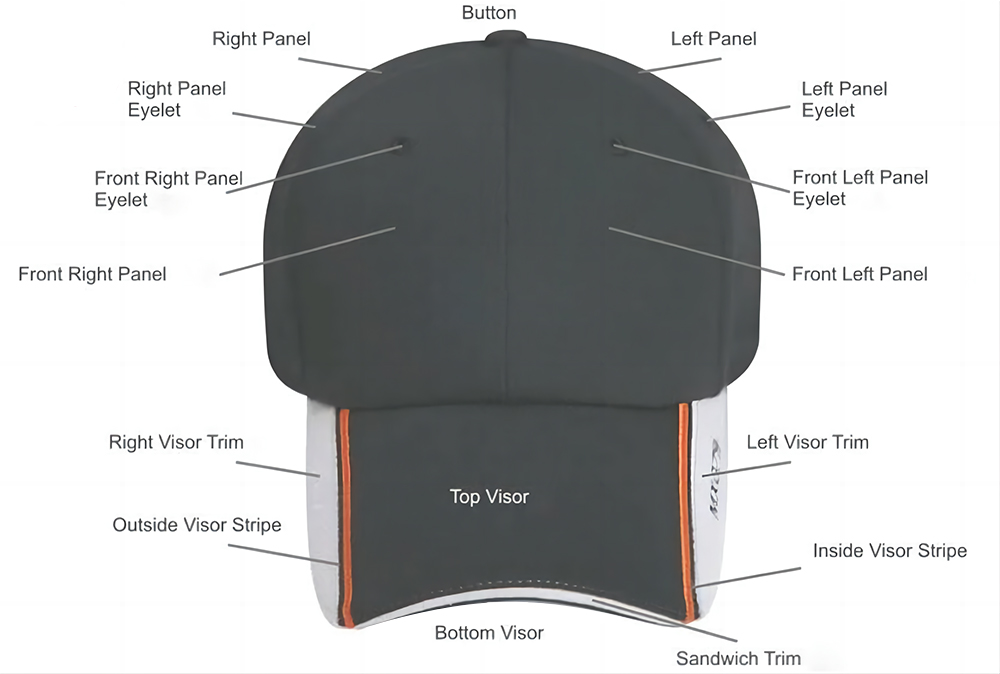

The process of making the caps starts with knowing about the components of the cap. Every baseball cap comprise the following components:

3. Embroidery on the panels. After this, the front panel is sent to the embroidery department where distinct logos and graphics are embroidered onto the front panels through computerized embroidery machines.

4. Attach eyelets on the panels. After embroidery, the panels are sent to eyelet machines where the machine pierces through the panel and stitch around its edges.

5. Attach tapes. With most of the caps being 6-paneled caps the stitching starts with stitching 3 panels together twice which is stitched in between and reversed to form the crown. These tapes ensure that the seams give a soft feel to the wearer at the seams.

6. Make the visor part. Alongside the crown, the front visor is made by stitching two fabric panes like a pocket and turning it inside out. The material to be put inside the visor can range from stiff fabric to plastic sheet depending on the requirement. This is mostly done through automatic stitching machines for the highest quality.

7. Attach sweatband. With the visor attached, the sweatband is attached to the base of the crown followed by a decorative topstitch at the base of the cap. During this labels can be added to the sweatband.

8. Attach cloth snaps (button). The final stage is the addition of the cloth snaps at the top of the cap where all the panel seams converge.

9. Attach Closure. At the back of the cap attach an adjustable closure. This can be made of self-fabric or plastic closure.

10. Steaming the stitched cap. After stitching is complete, the caps are placed on a blocking machine that steams and fixes the shape of the cap. This ensures a greater life span of the caps as they are less likely to lose their shape after that.

The above is the process of making baseball caps.We are a professional hat manufacturer. We know how important the quality of the hat is for customers, so we strictly control each production process of the hat. It is precisely because of our serious and responsible attitude that it produces a high -quality hat and obtain it. With the recognition of customers, now our customers are all over the world, and we will continue to work hard to make better hats.https://www.cdhbfedorahat.com/

Contact: Rebekah Wong

Phone: 18631261092

Tel: 86-18631261092

Email: rebekah@cdhbtech.com

Add: 1710, Block C, Diangu Office Building, Jingxiu District, Baoding City, Hebei Province

We chat